Description

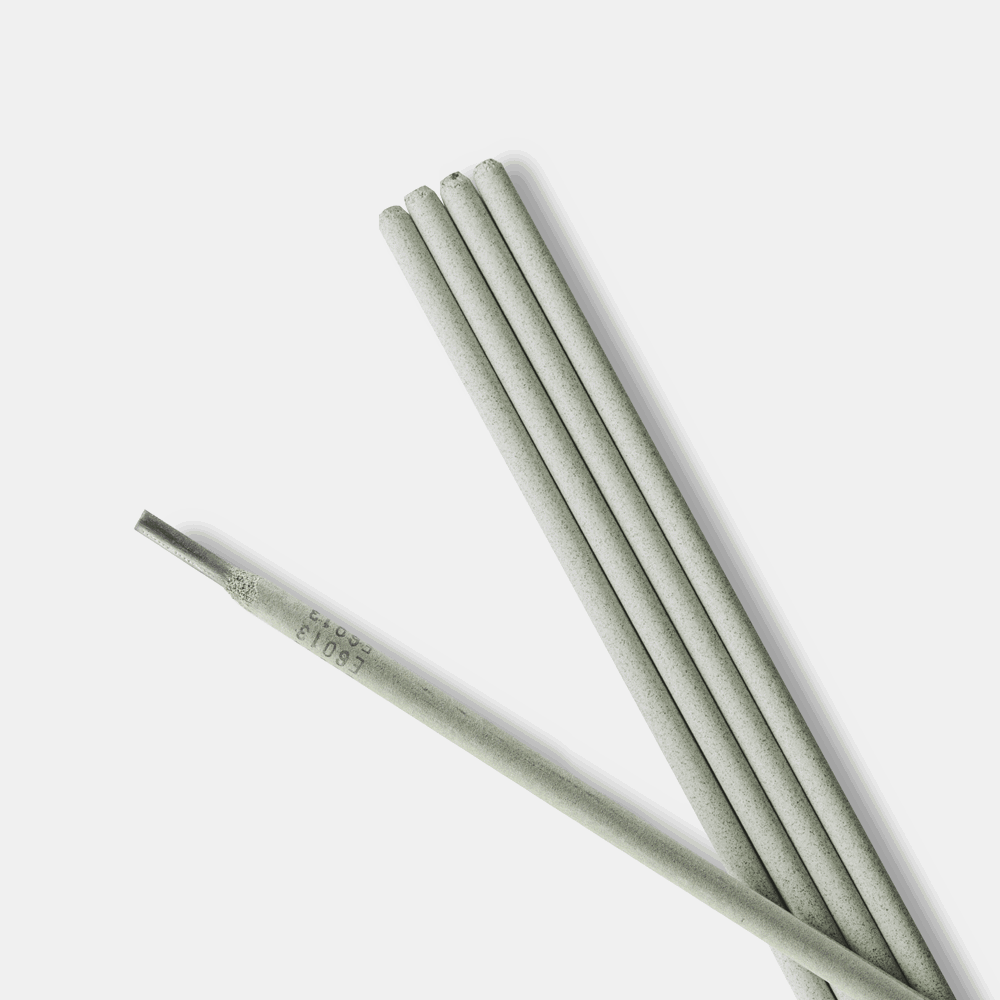

Washington Alloy E6013 HF Electrode (2.0mm) 5/64″ – (price per lb)

E6013: Produces a smoother weld, commonly used for thin metal and sheet welding.

E6013 electrodes, while being 2mm (or about 5/64″) thick, are still commonly used for thin sheet welding because of the characteristics of the rod and the way it performs during the welding process. Here’s why they work well for thin sheets:

1. Soft Arc and Lower Penetration: E6013 rods have a relatively soft arc compared to other rods, meaning they don’t penetrate as deeply into the metal. This is important for thin sheets, as deep penetration can lead to burn-through or warping of the material.

2. Fast-Freezing Slag: The slag produced by E6013 rods cools quickly, which helps control the heat input and allows for better control over the weld pool. This is crucial when welding thin sheets, where excess heat can cause distortion or damage.

3. Versatility in Position: E6013 can be used in various welding positions, including vertical and overhead. This adaptability makes it useful for thin, flexible sheet metal, which may not always be in the ideal flat position.

4. Easy Restart and Control: E6013 rods are known for being easier to restart and control, which is beneficial when making short, controlled welds on thin metal sheets. You can stop and start as needed without risking overheating the workpiece.

Though the rod itself may seem a bit thick, the way it melts and deposits metal onto the workpiece allows it to handle thin metals efficiently without causing damag